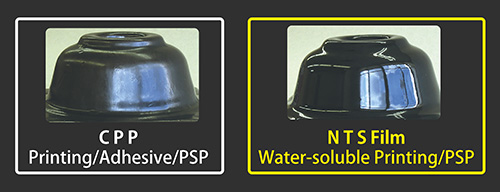

NTSII [PP Film for New Container Bonding]

High-added value (heat resistant, glazed, oil resistant) containers can be designed, and it is possible to reduce costs in relation to the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging.

Nakamoto successfully developed a thin PP film that is high gloss, heat resistant, and oil resistant, that does not exist in conventional PP and PS films used for bonding, by implementing our company’s unique water soluble printing (adhesion between different materials) on PP film that can be thermoformed, that was originally devised by Nakamoto.

NTSII Features

- This is a highly glossy film, so the surface of container molded products has a high glossy finish.

- This is also a highly rigid film, so it can be used as a thin film (supports thinnesses up to 12µ), and supports the Act on the Promotion of Sorted Collection and Recycling of Containers and Packaging.(Approximately half the weight of PS film of 25µ [per m2])

- This is also a highly heat-resistant film, so it is perfect for bonding films to containers used in microwave ranges.

- This is a PP material film, so containers that are oil resistant can be manufactured.

- It is implemented with water-soluble printing ink that adheres to not only PP Solid and PPF but also PSP, making it perfect for the environment.

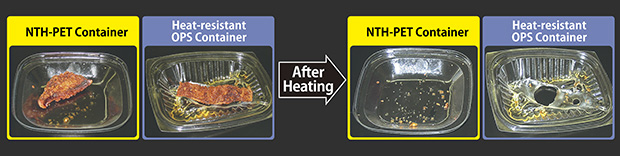

NAK-A-PET [Transparent, High-Heat Resistant PET Sheet]

Transparent material with amazing heat resistance unlike conventional A-PET.

Our company has developed a sheet for heat molding that is highly heat resistant beyond common sense, and transparent by implementing a special heat molding using our own devised PET sheet.

This is a new type of sheet for heat molding that imparts heat resistance unseen in conventional A-PET materials, and solves the opacity of C-PET all at once.

Perfect for transparent blister containers that require high-heat resistance, also for food containers and lids.

NAK-A-PET Features

- Maintains the transparency equivalent to A-PET even after heat molding.

- Fully variations even at heat-resistant temperatures of 80˚C - 150˚C.

- In a high-heat resistant grade, the container does not deform even if used in a microwave oven for oily foods.

- This is also a highly rigid sheet, so it contributes to resource saving because the container can be thin.

- Excellent bending characteristics.

- Recyclable, in the same way as A-PET.

- Highly transparent, so you can promote the appearance of your food product and the packaging materials.

| NAK-A-PET | A-PET | PP | OPS | |

| Transparency | ○ | ○ | △ | ◎ |

| Heat Resistance | ◎ | ✕ | ○ | △ |

| 80-150˚C | 65˚C | 110˚C | 80˚C | |

| Oxygen Barrier | ○ | ○ | ✕ | ✕ |

| Oil Resistance | ◎ | ◎ | ○ | ✕ |

| Rigidity | ◎ | △ | ✕ | ◎ |

◎: Very good, ○: Good, △: Average, ✕: Unacceptable

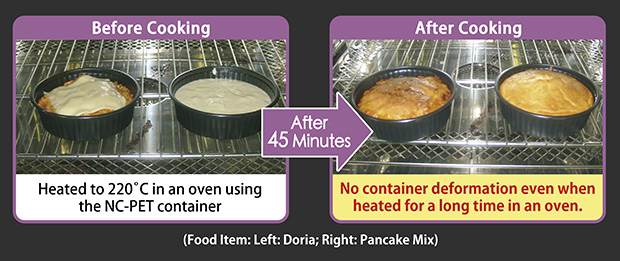

NC-PET [Super, high-heat resistance PET]

PET for ultra-heat resistance molding exceeding NAK-A-PET

This is an ultra-high heat-resistant sheet for molding developed from a fusion of recycled PET film technology and NAK-A-PET molding technology.

Its heat-resistance temperature is 220˚C! (Depends on molding conditions.)

Excellent fragrance-retaining property, and has almost no resin odor, so there is no worry even when using it as a food container.

This is a new generation of PET.

NC-PET Features

- This is an ultra-high heat resistant sheet for molding developed from a fusion of recycled PET film technology and NAK-A-PET molding technology.

- Heat-resistance temperature 220˚C (Our company test: Overheating test for 30 minutes in a hot-air oven set to 220˚C)

- NC-PET is a sheet for white and black colored containers.

- It is C-PET-like but the molding time can be made dramatically shorter than C-PET.

- The total cost can be reduced further than C-PET.